-

Address: China, Shenzhen

-

Email: info@chinaglobalhub.com

China Global Hub

China business solutions center

-

Phone: +86 188 0760 4383

-

Telegram: @china_global_hub

China Global Hub

China business solutions center

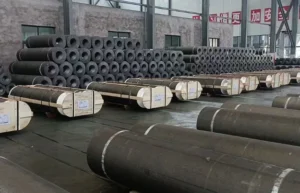

Graphite Electrode Production Technology: Buy & Deliver

Explore graphite electrode production technology from China and learn how to buy, order, and deliver high-quality electrodes worldwide with China Global Hub.