-

Address: China, Shenzhen

-

Email: info@chinaglobalhub.com

China Global Hub

China business solutions center

-

Phone: +86 188 0760 4383

-

Telegram: @china_global_hub

China Global Hub

China business solutions center

Quality Control in Factories

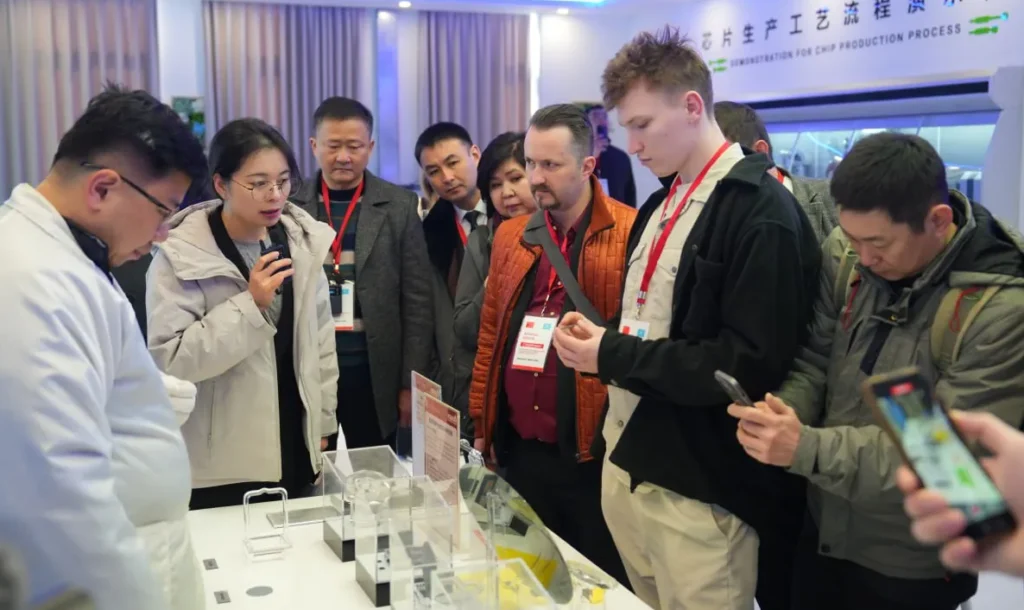

Quality control in factories in China with ChinaGlobal Hub

ChinaGlobal Hub provides professional quality control at all stages of production in China: factory audits, supplier checks, and finished product inspections. We minimize the risks of defects and delays, guarantee compliance with standards, and protect your company's reputation. Our comprehensive approach, transparent reports, and over 10 years of experience help create reliable and safe supply chains for your business.